Commercial Silo Repair

Expert and Knowledgeable Professionals

Hanson Silo’s repair team is trusted industry-wide.

Hanson Silo does commercial silo repair and elevator restoration services, including cracked, spalled and rotten concrete sealing, tuck pointing, hole patching and fixing decayed exposed rock caused by freeze/thaw cycles of expansion and contraction.

Our service and construction team have a combined total of 79 years of concrete silo industry experience, with an average tenure of 12 years. Hanson has the equipment and content knowledge to execute this job successfully.

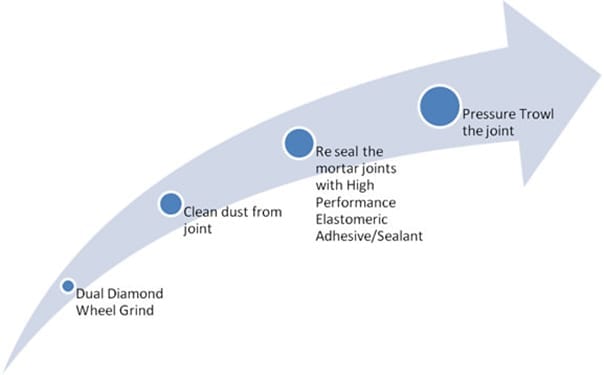

We recommend not using cement-based mortar as the best sealant for moisture. We use a method much better than traditional tuck pointing with mortar. Hanson Silo has many years of experience with this one-part industrial-grade bond for sealing cracks in poured concrete silos and grain elevators.

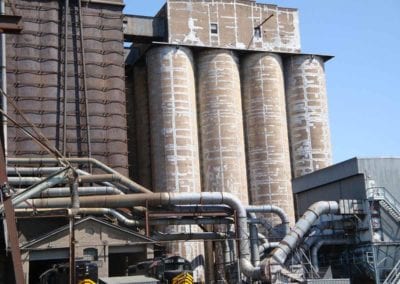

In the gallery, you’ll find an example of a best practices approach Hanson used on a large annex on a commercial grain poured concrete silo restoration project for a major food manufacturer.

Call Hanson at 320.664.4171 for More Information About Commercial Silo Repair

HANSON SILO DOES COMMERCIAL CONCRETE ELEVATOR RESTORATION SERVICES, INCLUDING:

Below is an example of a best practices approach we used on a large annex on a commercial grain poured concrete silo restoration project for a major food manufacturer.

THE HANSON TUCK POINTING APPROACH

- Precast Concrete

- Agricultural Storage

- Bunker Walls

- Concrete Feed Bunks

- Hog Slats – Concrete Slatted Floor Systems

- Cattle Slats & Deep Pit Barns

- Grain Storage Systems

- Precast Grain Aeration Trench

- Fertilizer Flat Storage

- Feed Mills

- Commodity Shed

- Bulk Storage Guidelines & Bunker Calculator

- Commercial Storage

- Salt & Sand Storage

- Recycling Storage

- Misc. Bulk Storage

- Precast Concrete Wall Panels

- Precast Wall Panels for Car Dealerships

- Landscape & Recreation

- Shooting & Blast Walls

- Retaining Wall

- Picnic Tables

- Landscape Block

- Products

- EASY RAKE® Silage Facer

- Smart Manure Aeration Systems

- Big Foot Silage Packer

- Silo Roofs

- Secure Covers

- Animat Max Grip Slat Rubber

- Redneck Deer Stands

- Trioliet Feeding Technology

- TMR Mixer Feeder Wagons

- Stationary Mixer Feeder

- Tower Silo Products

- Silo Repair & Replastering

- Commercial Silo Repair

- Silo Rods

- Steel Concrete & Conversion Kit

- Wireless

- Valmetal Farm Feeding Equipment

- Autoration Robot Feeding Equipment

- Combox-Silage Reserve

- Silo Unloaders

- Belt Feeders and Conveyors

- TMR Mixers

- Bale Choppers

- Motorized Carts