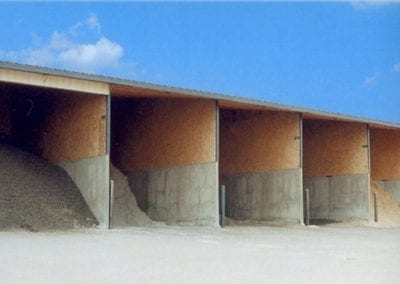

Commodity Shed

Home Hanson Silo Precast Concrete Agricultural Storage Commodity Shed

Flexibility for Future Expansion

Hanson’s experienced team can help plan shed configuration.

Hanson Silo precast bunker panels make building commodity sheds both easy and effective for current needs and flexible for future needs. Here are suggested questions to consider when planning your commodity shed:

- Do you want several small bays or a few large ones?

- What exactly are my needs?

- What are my needs going to be in 5 years?

Call Hanson at 320.664.4171 for More Information About Commodity Storage

PLAN YOUR COMMODITY STORAGE SHED

Below are additional pointers to help you better determine your commodity storage needs. Our sales team, comprised of more than 115 years of cumulative experience, is ready to help you plan your shed.

- Slope bays outward and peak the roof past the walls so rain and snow melt don’t flow into the storage bays.

- Pour the optional concrete floors after the precast walls have been set. This prevents water from leaking into an adjacent bay when cleaning between loads. It also saves a great deal of concrete due to the wall panels having built-in footings on the T design. Ultimately, this equates to less yards to buy from the ready-mix plant.

- Design the commodity shed to have two more bins than you think you need. This allows you to rotate feeds, clean bins between loads and pre-mix commodities, if desired.

- If your system is getting too costly, leave those two bins out and they can easily be added later.

- Slope the concrete apron in front of the bays away from the bays.

- Include a bay for dry rolling or processing grain as well as grinding hay.

- Precast Concrete

- Agricultural Storage

- Bunker Walls

- Concrete Feed Bunks

- Hog Slats – Concrete Slatted Floor Systems

- Cattle Slats & Deep Pit Barns

- Grain Storage Systems

- Precast Grain Aeration Trench

- Fertilizer Flat Storage

- Feed Mills

- Commodity Shed

- Bulk Storage Guidelines & Bunker Calculator

- Commercial Storage

- Salt & Sand Storage

- Recycling Storage

- Misc. Bulk Storage

- Precast Concrete Wall Panels

- Precast Wall Panels for Car Dealerships

- Landscape & Recreation

- Shooting & Blast Walls

- Retaining Wall

- Picnic Tables

- Landscape Block

- Products

- EASY RAKE® Silage Facer

- Smart Manure Aeration Systems

- Big Foot Silage Packer

- Silo Roofs

- Secure Covers

- Animat Max Grip Slat Rubber

- Redneck Deer Stands

- Trioliet Feeding Technology

- TMR Mixer Feeder Wagons

- Stationary Mixer Feeder

- Tower Silo Products

- Silo Repair & Replastering

- Commercial Silo Repair

- Silo Rods

- Steel Concrete & Conversion Kit

- Wireless

- Valmetal Farm Feeding Equipment

- Autoration Robot Feeding Equipment

- Combox-Silage Reserve

- Silo Unloaders

- Belt Feeders and Conveyors

- TMR Mixers

- Bale Choppers

- Motorized Carts