Cattle Slats & Deep Pit Barns

Combinations Maximize Efficiency

Hanson slatted confinement systems offer better performance.

The goal is to separate the waste from the animal as quickly, efficiently and with the least amount of stress as possible. With over 100 years of dry cast concrete and cattle feeding experience, Hanson Silo’s slatted floor systems offer better cattle efficiency, full manure values, reduced maintenance and labor costs, and superior cattle comfort and performance. We can supply just the slats or a combination of the slats, beams, precast concrete columns, feed bunks, & Precast commodity shed.

Call Hanson at 320.664.4171 for More Information About Cattle Slat Floor Systems

HANSON SLATTED FLOOR SYSTEMS

Hanson beef confinement systems perform better when looking at almost every major statistic (ADG, DMI, F/G, carcass quality). Cattle in 1 foot of mud from an outside lot can reduce dry matter intake by 30% or more. Studies have also found the negative impact of mud on feed efficiency can result in up to a 56% increase in the cost of gain. In the slat barn the cattle are able to make more trips to the feed bunk and also don’t expend as much energy by trudging through mud. We provide the cattle with year-round dry conditions, which promotes biosecurity, cleanliness, foot health, and feed efficiency. Research shows confinement cattle in deep-pit slat barns will have improved feed conversion by about 10 percent.

Not only do Hanson’s slat barns improve feed conversion, they also increase average daily gains (ADG). As an example, consider wet weather conditions in an outdoor lot. When producers have 100 days of extended wet weather, the outdoor lot can suffer 0.5 lb/day ADG drops. That’s 50 pounds at a market value of $140/cwt or $70/head in less than a half year. Because producers continue to experience more extreme weather patterns every year, Hanson’s deep-pit slat barns are a great investment.

REDUCED LABOR AND MAINTENANCE COSTS

Hanson’s slatted floor systems allow producers to reduce labor costs and eliminate costly bedding. The value of a producer’s time increases every year, as well as the value of saved time. According to the Beef Feedlot Systems Manual, the hours/head space/year required to feed cattle in an earthen lot is 0.28 hours, and comparatively, it only requires 0.14 hours to feed cattle in a slatted floor confinement. Not surprisingly, the most labor requirement can be found in a confinement with a bed-packed floor (0.38 hours). Using the feeding of 1,000 head of cattle for an example, that equates to 280 hours of labor in a dirt lot setting, 380 hours of labor in a confinement with a bed-packed floor, and only 140 hours of labor per year in a confinement with slatted floors. Build your cattle building with Hanson’s Robotic feeding and save even more hours.

A slatted-floor confinement requires absolutely no bedding. How much time and effort does it take to 1. put up cornstalk bales, 2. haul bales from field into the yard, 3. just to haul cornstalks back to the field with the manure?

This eliminates the need for costly equipment and labor. The average fat steer will need 0.61 bales/headspace/year. This equates to 610 bales to be used in a 1,000 head operation every year at an average cost of $25/bale = $15,250. This cost is also added to the labor and equipment costs of using bedding. If you combine the bale cost, equipment, scraping, and spreading of bedding, you will spend roughly $64.31/head space. In Hanson’s slatted confinement systems, there is no added cost for bedding.

SUPERIOR CATTLE COMFORT

With Hanson Silo’s slatted cattle buildings, cattle stay cooler in the summer and warmer in the winter. As previously mentioned Hanson Silo’s slat system requires absolutely no bales for bedding.

- Better feed conversion

- Rubber mats on slats improve cushion, comfort and cattle movement, reduce lameness and tail injury and higher gains

- Animals observed on the rubber slat mats showed increased activity, improved comfort and heat behavior and reduced mechanical-traumatic claw findings

- More frequent trips to the feed bunk

- Increases animal confidence, comfort and welfare

- Reduces lameness

- Texture-enhanced foothold and comfort – almost the same as pasture

- Lower thermal conductivity and better insulation, ensuring more comfortable animals

When making a million-dollar decision, don’t try to save a few bucks by skimping. Do it right the first time and buy Hanson.

- Slat-over-pit system:

- Optimizes cattle density in finishing operations for improved profit potential

- Eliminates the need for bedding and all of the associated costs of bailing crop residues and bedding

- Maximizes nutrient value to minimize fertilizer costs

- Pump once per year 12 month storage

- Unbeatable organic matter in soil grows the best corn

- Top Slat Width

- 7″ Thickness

- 1 5/8″ Slot Spacing

- 4′ Maximum Width

- 4′ x 12′ Standard – Other sizes are special order

- Wear Edge

- Rota-screeded & Machine Vibrated

Hanson Silo recommends producers absolutely should invest in rubber mats on the slatted floors. Hanson Silo is a dealer for Animat, Easy Fix & Titan.

SLAT RUBBER ADVANTAGES

When you purchase Hanson products, you benefit from more than 100 years of experience in producing innovative concrete products of the finest quality. We use only superior grade materials and apply the latest technology (including computerized batching controls) in the manufacturing processes. We maintain our own testing labs to ensure that Hanson products provide the ultimate in durability and endurance. At Hanson, your satisfaction is our number one concern.

Hanson offers solutions for both precast concrete wall pits or can supply slats on your cast-in-place pit wall and post barn. Hanson can build a new system or deliver replacement slats in your existing system. The precast pit manure storage system is NRCS pre-qualified, versatile, and expandable.

COMPARE THESE ADVANTAGES

- $106 per head per year estimated of N, P and K value

- Lowest labor input of any system

- No machinery maintenance problems

- No daily labor required for operation of equipment

- No electric power needed; saves energy

- Livestock stay cleaner, more comfortable

- Precast slatted floor systems require less square footage per animal

Panels are manufactured under controlled factory conditions using state-of-the-art technology.

- Precast Concrete

- Agricultural Storage

- Bunker Walls

- Concrete Feed Bunks

- Hog Slats – Concrete Slatted Floor Systems

- Cattle Slats & Deep Pit Barns

- Grain Storage Systems

- Precast Grain Aeration Trench

- Fertilizer Flat Storage

- Feed Mills

- Commodity Shed

- Bulk Storage Guidelines & Bunker Calculator

- Commercial Storage

- Salt & Sand Storage

- Recycling Storage

- Misc. Bulk Storage

- Precast Concrete Wall Panels

- Precast Wall Panels for Car Dealerships

- Landscape & Recreation

- Shooting & Blast Walls

- Retaining Wall

- Picnic Tables

- Landscape Block

- Products

- EASY RAKE® Silage Facer

- Smart Manure Aeration Systems

- Big Foot Silage Packer

- Silo Roofs

- Secure Covers

- Animat Max Grip Slat Rubber

- Redneck Deer Stands

- Trioliet Feeding Technology

- TMR Mixer Feeder Wagons

- Stationary Mixer Feeder

- Tower Silo Products

- Silo Repair & Replastering

- Commercial Silo Repair

- Silo Rods

- Steel Concrete & Conversion Kit

- Wireless

- Valmetal Farm Feeding Equipment

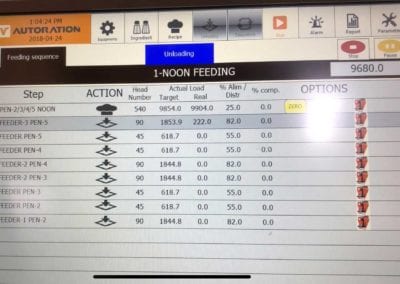

- Autoration Robot Feeding Equipment

- Combox-Silage Reserve

- Silo Unloaders

- Belt Feeders and Conveyors

- TMR Mixers

- Bale Choppers

- Motorized Carts