Feed Mills

Strength, Quality, and Flexibility

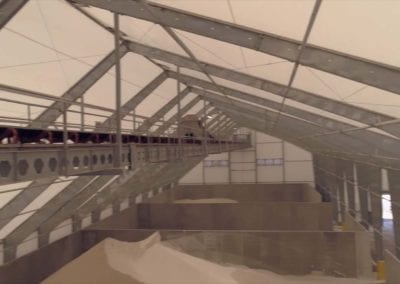

Hanson’s concrete panels effectively separate feed mill contents.

Feed mills have been a valuable source for farmers since the late 19th century. Some of the largest companies in America, including Cargill and Purina, also utilize concrete feed mills. They are vital for getting the right nutrients blended into a feed product so that farmers can give their cows the best nutrients.

Hanson Silo provides bunker panels for installation into feed mills to keep products separated. Our bunker system is a natural fit for feed mills all across the country because it provides a strength, flexibility, and speed that can’t be matched.

Hanson feed mill bunker panels have been pre-engineered to take a weight of even the heaviest feed products, up to 130 lbs. per cu ft. We can achieve this by having the strongest mix on the market, typically double what most poured walls come in at. Hanson also has the heaviest rebar and mesh schedule in the industry and can add in rebar dowel splicers to the toe and tie the panels directly to the slab, preventing slide.

The bunker panels come in 7 different heights, meaning that you don’t have to pay for extra concrete in the air that will never have product against it.

Call Hanson at 320.664.4171 for More Information About Concrete Feed Mills

Hanson precast concrete feed mill panels are portable: you can change bay sizing, add on, or trade up to larger panels as your needs change. The walls hold their value over long periods of time because of the strength and durability in which they are made.

Most installations can be completed in a matter of days. Hanson Silo has installed panels at feed mills with a capacity of over 40,000 tons in 4 days. If you have an existing building, the panels can be set on top of your existing concrete and special angle iron slide prevention can be installed that will prevent movement.

Precast Concrete Feed Mill Panels

With the strength of Hanson’s panels, you can build directly on top of existing structures and save yourself time and money with installation. We have customers that have put stick built, post frame, hoop, and steel building up depending on your building preference. Hanson has experience working with some of the premier building contractors in the country and have sent panels to California, Texas, North Carolina, Maryland, and others because we offer a quality that can’t be matched.

- Precast Concrete

- Agricultural Storage

- Bunker Walls

- Concrete Feed Bunks

- Hog Slats – Concrete Slatted Floor Systems

- Cattle Slats & Deep Pit Barns

- Grain Storage Systems

- Precast Grain Aeration Trench

- Fertilizer Flat Storage

- Feed Mills

- Commodity Shed

- Bulk Storage Guidelines & Bunker Calculator

- Commercial Storage

- Salt & Sand Storage

- Recycling Storage

- Misc. Bulk Storage

- Precast Concrete Wall Panels

- Precast Wall Panels for Car Dealerships

- Landscape & Recreation

- Shooting & Blast Walls

- Retaining Wall

- Picnic Tables

- Landscape Block

- Products

- EASY RAKE® Silage Facer

- Smart Manure Aeration Systems

- Big Foot Silage Packer

- Silo Roofs

- Secure Covers

- Animat Max Grip Slat Rubber

- Redneck Deer Stands

- Trioliet Feeding Technology

- TMR Mixer Feeder Wagons

- Stationary Mixer Feeder

- Tower Silo Products

- Silo Repair & Replastering

- Commercial Silo Repair

- Silo Rods

- Steel Concrete & Conversion Kit

- Wireless

- Valmetal Farm Feeding Equipment

- Autoration Robot Feeding Equipment

- Combox-Silage Reserve

- Silo Unloaders

- Belt Feeders and Conveyors

- TMR Mixers

- Bale Choppers

- Motorized Carts