About Us: Hanson Companies History

Symbolizing Quality and Dependability

Hanson has been rooted in agriculture for four generations.

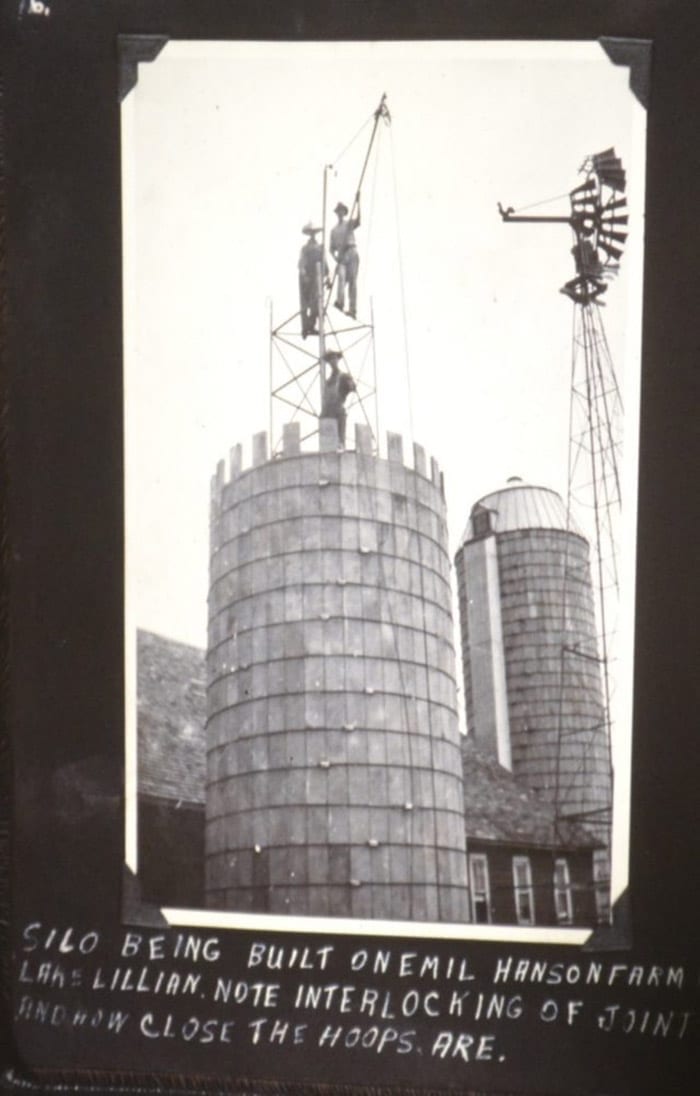

Hanson Companies was founded in Lake Lillian, Minnesota, in 1916 by Emil Hanson, a local farmer who envisioned a better silo product for himself and for his neighbors. His goal: manufacture an improved silo at the best price with the lowest upkeep. For over 100 years and through four generations, the Hanson family has been involved with agriculture and has grown to symbolize quality, economy and dependability.

The family farming tradition has remained at Hanson Companies, as well as the commitment to producing the best quality product for the dollar. The development of new Hanson products is the culmination of this commitment. We excel in a range of areas, including livestock feed storage and handling equipment, grain storage, precast concrete products and powder coating industries. Fine quality materials, pride in personal workmanship and simplicity in engineering are the trademarks of Hanson Companies.

1916

During World War I, Emil Hanson, a local farmer from Lake Lillian, Minnesota, was looking to purchase a silo for his farm and found an abundance of poorly constructed silos in the area. Emil noticed that the sand was full of dirt and clay, which resulted in poor concrete for the construction of these silos. Emil had the idea to create a more durable concrete using sand from the shore of Lake Kandiyohi, the lake his farm bordered. The product, which used a washed sand, is now used by concrete manufacturers around the world.

During World War I, Emil Hanson, a local farmer from Lake Lillian, Minnesota, was looking to purchase a silo for his farm and found an abundance of poorly constructed silos in the area. Emil noticed that the sand was full of dirt and clay, which resulted in poor concrete for the construction of these silos. Emil had the idea to create a more durable concrete using sand from the shore of Lake Kandiyohi, the lake his farm bordered. The product, which used a washed sand, is now used by concrete manufacturers around the world.1920s

1930s

1940s

1960s

1970s

1980s

Hanson increased production on a new industrial strength silo stave by implementing a completely automated computer controlled concrete machine.

Hanson increased production on a new industrial strength silo stave by implementing a completely automated computer controlled concrete machine.

1986 – Hanson designed and built a golf car manufacturing plant called Shuttlecraft in Willmar, Minnesota, to diversify their product portfolio in the midst of the agriculture crisis of the ’80s.

1990s

Hanson further expanded their silo unloader line.

Hanson further expanded their silo unloader line.

1995 – Hanson built their first precast concrete plant.

1996 – Powder coat painting was implemented, opening the door into contract manufacturing. Truck beds, assembly-line automation equipment and electronic scoreboards for major sports complexes, among other products, were engineered and manufactured.

2000s

Hanson expanded their powder coating system from a 5-person manual moving line to the 10′ x 10′ x 40′ batch booth and implemented a 14-gun computerized automatic spraying line. Hanson also designed and built a computer-controlled automated concrete batch plant. This world-class plant could mix three yards of low-slump 7,000 psi ready mix in 90 seconds.

Hanson expanded their powder coating system from a 5-person manual moving line to the 10′ x 10′ x 40′ batch booth and implemented a 14-gun computerized automatic spraying line. Hanson also designed and built a computer-controlled automated concrete batch plant. This world-class plant could mix three yards of low-slump 7,000 psi ready mix in 90 seconds.- Precast Concrete

- Agricultural Storage

- Bunker Walls

- Concrete Feed Bunks

- Hog Slats – Concrete Slatted Floor Systems

- Cattle Slats & Deep Pit Barns

- Grain Storage Systems

- Precast Grain Aeration Trench

- Fertilizer Flat Storage

- Feed Mills

- Commodity Shed

- Bulk Storage Guidelines & Bunker Calculator

- Commercial Storage

- Salt & Sand Storage

- Recycling Storage

- Misc. Bulk Storage

- Precast Concrete Wall Panels

- Precast Wall Panels for Car Dealerships

- Landscape & Recreation

- Shooting & Blast Walls

- Retaining Wall

- Picnic Tables

- Landscape Block

- Products

- EASY RAKE® Silage Facer

- Dairy Power Smart Manure Aeration Systems

- Big Foot Silage Packer

- Silo Roofs

- Secure Covers

- Animat Max Grip Slat Rubber

- Redneck Deer Stands

- Tower Silo Products

- Silo Repair & Replastering

- Commercial Silo Repair

- Silo Rods

- Steel Concrete & Conversion Kit

- Wireless

- Valmetal Farm Feeding Equipment

- Autoration Robot Feeding Equipment

- Combox-Silage Reserve

- Silo Unloaders

- Belt Feeders and Conveyors

- TMR Mixers

- Bale Choppers

- Motorized Carts